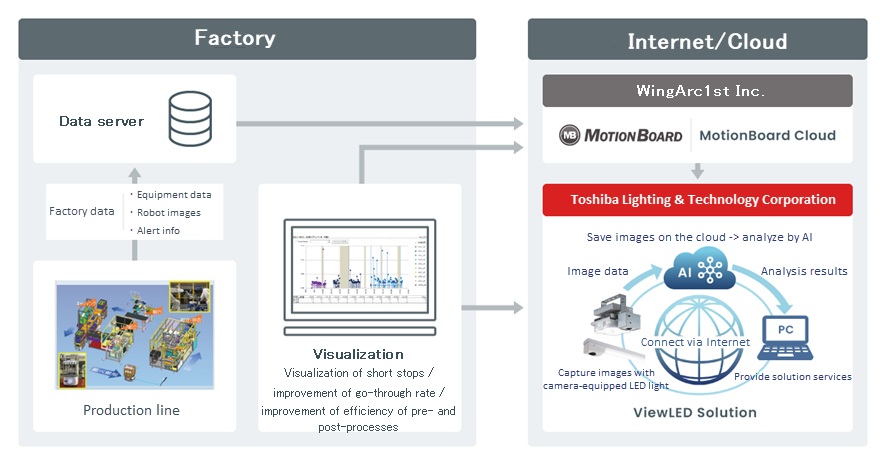

MotionBoard integrates with ViewLED Solution

Mapping equipment data and images to improve efficiency in production sites

WingArc1st Inc.

Toshiba Lighting & Technology Corporation

On 20 June WingArc1st Inc. and Toshiba Lighting & Technology Corporation will launch a service for visualizing production status. The service integrates WingArc's BI dashboard, MotionBoard, with Toshiba's cloud AI image analysis service, ViewLED Solution.

MotionBoard has an extensive track record of implementation in manufacturing and excels at visualizing data generated at manufacturing sites, while ViewLED Solution is a cloud service for AI image analysis and long-term storage of images captured by camera-equipped LED lights.

Toshiba had been improving production efficiency by using these two services at a plant in Kanuma, and it came up with the idea of mapping equipment data with images. This integration enables mapping not only of facility data in MotionBoard, but also bright, clear birds-eye view images taken by a camera-equipped LED light, as well as the results of image analysis performed by ViewLED Solution.

■Features of Service

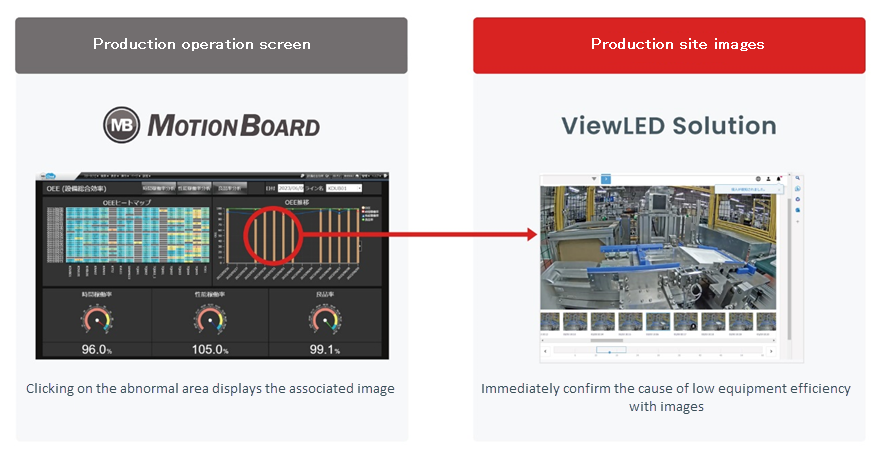

1. Mapping equipment data to image data to identify issues

You can identify the potential cause of an issue by obtaining relevant image data from MotionBoard from the time when facility data changed to confirm the situation with a bright and clear image captured by ViewLED Solution.

2.Confirm equipment malfunctions with images in MotionBoard, determine the cause, and return to the normal process.

You can identify errors at an early stage by mapping camera images to data showing equipment abnormalities in MotionBoard. For example, when the equipment stops, you can check the status by viewing the associated images. This means improved production efficiency because you can restore the equipment more quickly. You can also click on the graphs that indicate abnormal conditions to display a user interface that displays the associated images, allowing you to intuitively understand the situation at the facility.

The integration between MotionBoard and ViewLED Solution allows you to map equipment data with the relevant images, and display them in the MotionBoard UI. You can then easily detect errors, and improve operating and yield rates.

They will exhibit at the Manufacturing DX Exhibition at Tokyo Big Sight from 21 to 26 June.

https://event.wingarc.com/exhibition/japan-mfg2023 (Japanese)

■ Service summary

MotionBoard

A dashboard that transforms data from manufacturing sites into valuable information and provides an intuitive view of real-time status. MotionBoard can also be used for IoT applications. It is a solution that can contribute to solving customers' issues and has been implemented by more than 3,100 companies not only in manufacturing but also across a wide variety of industries.

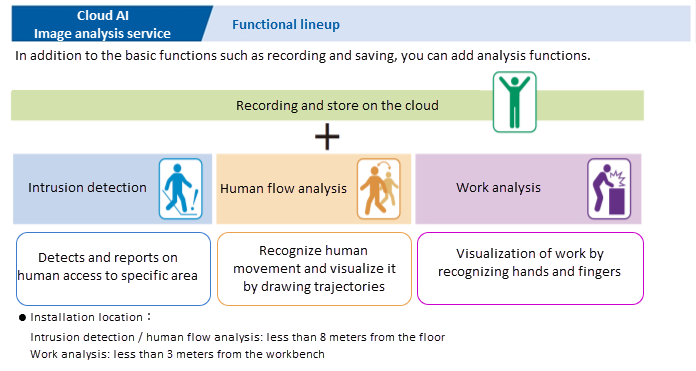

ViewLED Solution

Images captured by camera-equipped LED lights can be used for long-term storage and AI image analysis. By utilizing the captured data, safety management, site improvement effects, and economic effects can be enhanced.

・Intrusion detection: Detect and report on human access

・Human flow analysis: Recognize people and visualize them by drawing trajectories

・Work analysis: detect hand positions and movement, quantify results and generate reports

・Long-term recording and storage, and remote monitoring

■ Product introduction

MotionBoard: https://www.wingarc.com/en/product/motionboard/index.html

ViewLED and ViewLED Solution: https://www.tlt.co.jp/tlt/products/viewled/viewled_solution/lineup.htm (Japanese)

■Service start date

20 June 2023

This service will be exhibited at the Manufacturing DX Exhibition to be held at Tokyo Big Sight from June 21 to 23.

Contact on Products and Services:

WingArc1st Inc.

Roppongi Grand Tower, 3-2-1 Roppongi, Minato-ku, Tokyo106-0032, Japan

TEL : 81-3-5962-7300

FAX : 81-3-5962-7301

E-mail :

■ Contact for the ViewLED Solution:

Toshiba Lighting & Technology Corporation

E-mail:TLT-ViewLED-team@ml.toshiba.co.jp

*Company names and product names enlisted in this Press Release are trademarks or registered trademarks of each company.